The importance of braking systems cannot be overstated in heavy machinery and industrial equipment. Whether it’s cranes lifting heavy loads on construction sites, gantry cranes in warehouses, or hoists in manufacturing facilities, reliable braking systems are crucial for safety, efficiency, and precision. However, not all brakes are created equal, and different industries require specific braking solutions tailored to their unique needs and operational requirements. This guide delves into the world of industrial braking systems, exploring the different types of brakes and their applications across various industries.

The Role of Brakes in Industrial Machinery

Brakes in industrial machinery serve a critical function: to control the movement and speed of heavy loads, ensuring safety and precision in operation. Whether stopping a crane’s hoist quickly in an emergency or maintaining a controlled descent during lowering, the performance of industrial braking systems is paramount.

Types of Industrial Brakes

Industrial braking systems come in various types, each designed for specific applications and operating conditions. Some common types of industrial brakes include:

- Electromagnetic Brakes: These brakes use an electromagnetic field to generate braking force, making them suitable for applications requiring quick and precise braking, such as hoists and winches.

- Hydraulic Brakes: Hydraulic brakes use hydraulic pressure to apply braking force, offering high braking torque and excellent control. They are commonly used in heavy-duty applications such as cranes and construction equipment.

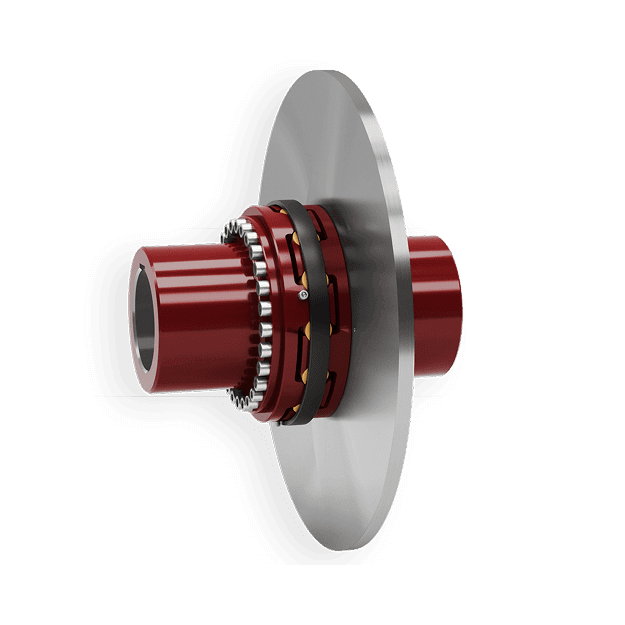

- Disc Brakes: Disc brakes use friction pads to clamp onto a rotating disc, providing reliable braking performance and heat dissipation. They are suitable for high-speed applications and are often found in industrial machinery and vehicles.

- Drum Brakes: Drum brakes consist of brake shoes that press against the inner surface of a rotating drum, offering robust braking performance and durability. They are commonly used in hoists, conveyors, and material handling equipment.

Tailoring Brakes to Industry Needs

- Construction Industry: Cranes and hoists are essential for lifting heavy materials and equipment. Industrial braking systems used in construction cranes must be capable of withstanding harsh environmental conditions, such as dust, dirt, and moisture while providing reliable braking performance to ensure safety on construction sites.

- Warehousing and Logistics: Gantry cranes and hoists are vital in warehousing and logistics operations, facilitating the movement and storage of goods and materials. Industrial braking systems used in gantry cranes must offer precise control and smooth operation to maximise efficiency in busy warehouse environments.

- Manufacturing Sector: In manufacturing facilities, hoists and cranes are used for various tasks, including material handling, assembly, and maintenance. Industrial braking systems employed in manufacturing equipment must provide high braking torque and consistent performance to ensure smooth operation and worker safety.

Factors to Consider When Choosing Braking Systems

- Load Capacity: The industrial braking system must be capable of handling the maximum load capacity of the crane or hoist to ensure safe operation.

- Operating Environment: Consideration must be given to the environmental conditions in which the equipment will operate, such as temperature, humidity, and exposure to dust or chemicals.

- Control and Precision: Industrial braking systems should offer precise control over braking force and speed to ensure smooth and accurate operation in industrial applications.

- Maintenance Requirements: Choose industrial braking systems that are easy to maintain and service to minimise downtime and ensure long-term reliability.

Contact Huebner Speed Monitoring for details

Industrial braking systems are critical components of cranes, hoists, and other heavy machinery used across various industries. By selecting the right braking system tailored to each industry’s specific needs and operational requirements, businesses can ensure safety, efficiency, and reliability in their operations. Whether it’s electromagnetic brakes for quick and precise braking or hydraulic brakes for high braking torque, choosing the appropriate braking system is essential for the smooth and safe operation of industrial equipment. As industries evolve and innovate, the demand for advanced braking solutions that deliver optimal performance and reliability will only grow, emphasising the importance of understanding the specific brake requirements for specific industries.

Please contact us today for more information about the industrial braking systems we distribute. Alternatively, please browse the extensive inventory of high-quality industrial brakes we distribute.