In heavy industry, where towering cranes, conveyors, wind turbines, and mining equipment operate under high stress, the ability to safely stop, hold, or control movement is critical. That’s where industrial braking systems play a vital role. Often overshadowed by more visible components, brakes are the unseen force ensuring operational safety, system integrity, and worker protection.

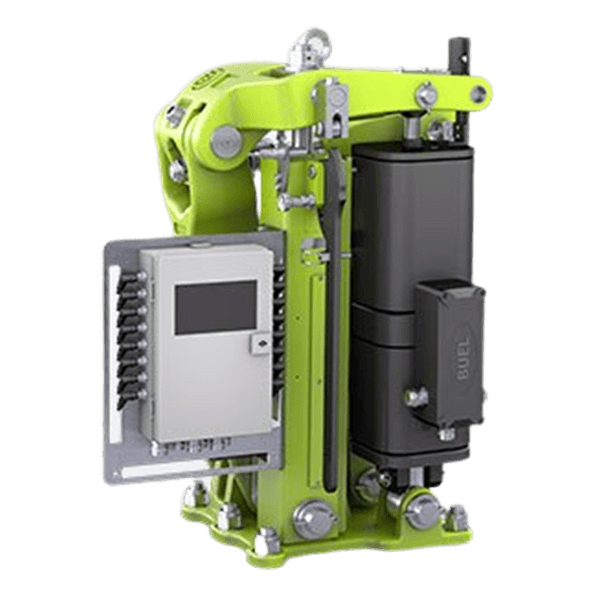

Huebner Speed Monitoring, a leading South African distributor, proudly supplies premium Dellner Bubenzer braking solutions. Designed for both static and dynamic applications, these advanced industrial braking systems are trusted across mining, steel, marine, and material handling industries where reliability and performance are non-negotiable.

What Are Industrial Braking Systems?

Industrial braking systems are engineered mechanisms that control, stop, or hold industrial equipment by applying friction or resistance. These systems are essential in applications requiring safety, load control, or precise stopping.

They are typically categorised as:

- Dynamic Brakes: Slow down or stop moving equipment (e.g., hoists, conveyors)

- Static Brakes: Hold a load or machine component in a fixed position (e.g., wind turbine blades, crane arms)

- Emergency Brakes: Automatically engage in power or system failure scenarios

Unlike standard vehicle brakes, industrial braking systems must endure extreme environments, heavy loads, and non-stop operation, necessitating specialised, high-performance components.

Why Industrial Braking Systems Are Critical for Safety

- Preventing Runaway Equipment: Industrial braking systems ensure that machines stop safely and reliably, even under high speeds or full load. This reduces the risk of damage to assets and danger to personnel.

- Load Control and Positioning: Braking systems help maintain the precise positioning of machinery components, which is essential in applications like cranes, elevators, and winches.

- Emergency Stopping: In the event of a power loss or mechanical failure, spring-loaded or hydraulically activated brakes can automatically engage to stop or secure the machine.

- Minimising Mechanical Wear: Controlled stopping and holding reduce stress on gearboxes, motors, and other moving parts, extending the lifespan of critical systems.

- Enhancing Operator Safety: A reliable braking system reduces reliance on human intervention and ensures safety protocols are executed automatically, reducing the risk of operator injury.

Dellner Bubenzer: Engineering Excellence in Braking

Dellner Bubenzer is a global leader in braking technology, known for its robust design, precise engineering, and industry-specific solutions. As an authorised distributor, Huebner Speed Monitoring has full access to its diverse range of industrial braking systems.

Notable Dellner Bubenzer Brake Products

- Disc Brakes (Hydraulic/Spring-Applied): For high-speed dynamic braking in cranes, wind turbines, and rolling mills.

- Drum Brakes: Ideal for lifting and hoisting applications, offering consistent torque performance.

- Storm Brakes and Rail Clamps: Designed for rail-mounted cranes and port equipment, providing wind-load resistance.

- Emergency Calliper Brakes: Spring-loaded for failsafe stopping during power failures or control loss.

- Motor-Mounted Brakes: Space-efficient solutions for compact machinery and vertical drives.

Each system is crafted to meet specific load, speed, and environmental requirements, ensuring the right fit for every application.

Industries That Depend on Industrial Braking Systems

| Industry | Application | Braking System Used |

| Mining | Hoists, conveyors, and crushers | Hydraulic disc brakes, spring-applied brakes |

| Marine and Ports | Shipyard cranes, container loaders | Rail brakes, disc brakes, storm brakes |

| Steel and Manufacturing | Rolling mills, drive systems | Calliper brakes, drum brakes |

| Renewable Energy | Wind turbines, yaw and rotor brakes | Active and passive braking systems |

| Material Handling | Overhead cranes, gantry systems | Motor-mounted and disc brakes |

Customised Braking Solutions by Huebner Speed Monitoring

Not all machinery operates under the same conditions, which is why Huebner Speed Monitoring goes beyond off-the-shelf supply. We provide:

- Engineering consultations to determine system requirements

- On-site support and installation assistance

- Access to the full Dellner Bubenzer product catalogue

- Maintenance and inspection schedules for ongoing safety

- Local technical support for fast turnaround and reduced downtime

We aim to supply world-class industrial braking systems and support their performance through the entire lifecycle.

Key Features of Dellner Bubenzer Braking Systems

- High Torque Output: Handles extreme loads and demanding stopping requirements with precision.

- Fail-Safe Technology: Spring-loaded brakes that engage automatically when power fails.

- Corrosion-Resistant Materials: Perfect for marine and mining environments where moisture and chemicals are a threat.

- Minimal Maintenance Requirements: Engineered for long service life and reduced operational downtime.

- Advanced Control Integration: Brakes can be integrated into automation systems for enhanced control and safety monitoring.

Choosing the Right Industrial Braking System

When selecting a braking system, consider the following:

- Type of Application: Is it dynamic, static, or emergency?

- Load Characteristics: Weight, speed, and operating frequency

- Environmental Conditions: Temperature, humidity, dust, corrosives

- Available Space: Mounting area and installation constraints

- Power Source: Electric, hydraulic, or pneumatic activation

The team at Huebner Speed Monitoring will assess all variables to match your application with the ideal braking system from Dellner Bubenzer’s comprehensive range.

FAQs About Industrial Braking Systems

What is the difference between static and dynamic braking?

Static brakes hold a machine or load in place, while dynamic brakes stop a machine while it’s moving. Some systems combine both for added safety.

Are industrial brakes customisable?

Yes. Dellner Bubenzer brakes can be configured for different torque ratings, sizes, and environmental specifications.

How often should industrial brakes be serviced?

It depends on usage, but most systems should be inspected at least annually. Huebner Speed Monitoring offers service plans for optimal reliability.

Can I retrofit industrial brakes to existing machinery?

Yes. Our engineering team can help retrofit braking systems to enhance existing equipment without complete system replacement.

What makes Dellner Bubenzer stand out from other brands?

Dellner Bubenzer offers German-engineered precision, global reputation, and a wide selection of certified, high-performance brake systems designed for critical applications.

Safety Starts with the Right Brake

In industrial operations where failure is not an option, braking systems are the first line of defence against accidents, mechanical breakdowns, and safety violations. Whether your machinery lifts, spins, transports, or processes, reliable stopping power is essential.

With world-class products from Dellner Bubenzer and expert support from Huebner Speed Monitoring, South African industries can trust in industrial braking systems that prioritise performance, durability, and above all, safety.

Contact Huebner Speed Monitoring today to explore our range of industrial braking systems and discover the right solution for your equipment, environment, and peace of mind.