Flexible couplings are vital in machinery. They ensure the smooth transmission of power between two rotating shafts while accommodating misalignment and reducing vibration. They are essential in enhancing mechanical systems’ performance, reliability, and longevity.

Huebner Speed Monitoring: Your Partner in Reliable Flexible Couplings

At Huebner Speed Monitoring, we understand the critical role these couplings play in industrial applications. Our top-tier flexible couplings are designed to meet the demanding requirements of modern machinery, ensuring reliable performance and longevity. Our extensive range of Dellner Bubenzer industrial brake coupling hubs, discs, and drums offers the perfect solution for your specific needs.

Whether dealing with misalignment, vibration, or shock absorption challenges, our couplings provide the reliability and durability required to keep your operations running smoothly.

FAQs About Flexible Couplings

What is a flexible coupling?

- A flexible coupling is a mechanical device that connects two rotating shafts. It allows for the transmission of torque while compensating for misalignments and reducing vibrations.

What are the types of misalignments that flexible couplings can accommodate?

- Flexible couplings can accommodate angular, parallel, and axial misalignments, ensuring smooth power transmission between connected shafts.

Why are flexible couplings considered reliable?

- Flexible couplings are reliable due to their durability, ability to reduce maintenance needs, versatility in various applications, safety features, and ease of installation.

What materials are used in the construction of flexible couplings?

- Depending on the application requirements, these couplings can be made from various materials, including rubber, elastomers, and metals.

How do flexible couplings reduce vibration in machinery?

- Flexible couplings absorb and dissipate vibrational energy, preventing it from transferring to the connected machinery. Thus, they reduce wear and tear, noise, and operational inefficiency.

Can flexible couplings handle sudden shocks in industrial applications?

- Yes, flexible couplings are designed to absorb shocks and sudden changes in load, protecting the connected machinery from damage.

How do I choose the right flexible coupling for my application?

- Choosing the right flexible coupling depends on factors such as the type of misalignment, torque requirements, operating environment, and the specific needs of your machinery. Consulting with experts like those at Huebner Speed Monitoring can help you find the perfect solution.

Experience the Huebner Speed Monitoring Difference

By understanding how flexible couplings work and why they are reliable, you can make informed decisions about the components used in your industrial applications, ensuring optimal performance and longevity.

Understanding the Basics of Flexible Couplings

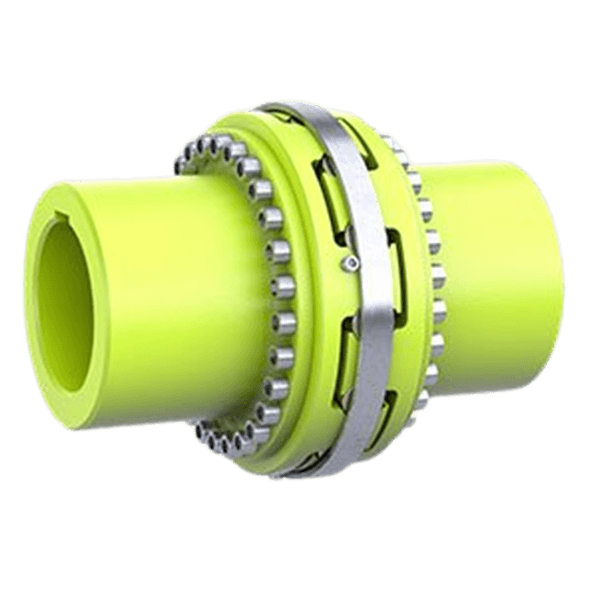

Flexible couplings are mechanical devices that connect two rotating shafts. They allow for the transfer of torque while compensating for minor misalignments and absorbing vibrations. They are commonly used in various industrial applications, including pumps, motors, compressors, and conveyors.

The primary function of a flexible coupling is to transmit power from one shaft to another while accommodating misalignments that can occur due to various factors such as thermal expansion, shaft deflection, or manufacturing tolerances. Unlike rigid couplings, which require precise alignment, flexible couplings offer flexibility, making them ideal for applications where perfect alignment is challenging to achieve.

How Flexible Couplings Work

- Torque Transmission: Flexible couplings transmit torque between two shafts by connecting them through a flexible element. Depending on the application requirements, this element can be made from various materials, including rubber, elastomers, or metal springs. The flexible element allows the coupling to accommodate misalignments while transmitting torque efficiently.

- Misalignment Compensation: One of the key advantages of these couplings is their ability to compensate for misalignments. There are three primary types of misalignment that flexible couplings can address:

- Angular Misalignment: This occurs when the shafts are not parallel and form an angle with each other.

- Parallel Misalignment: This happens when the shafts are parallel but not in line with each other.

- Axial Misalignment: Arises when the shafts move closer together or farther apart along their axis.

- Flexible couplings can absorb these misalignments, ensuring smooth and efficient power transmission without causing excessive stress on the connected machinery.

- Vibration Damping: Vibration is a common issue in rotating machinery, leading to wear and tear, noise, and reduced efficiency. Flexible couplings help dampen vibrations by absorbing and dissipating the energy, thereby protecting the machinery and extending its lifespan.

- Shock Absorption: In industrial applications, sudden changes in load or unexpected shocks can occur. They act as a buffer, absorbing these shocks and preventing damage to the connected equipment.

Why Are They Reliable?

Flexible couplings are renowned for their reliability in demanding industrial environments. Here’s why they are considered highly dependable:

- Durability: Flexible couplings are designed to withstand harsh operating conditions, including high temperatures, corrosive environments, and heavy loads. The materials used in their construction, such as high-quality elastomers and metals, ensure long-lasting performance.

- Reduced Maintenance: Because flexible couplings can accommodate misalignments and dampen vibrations, they reduce the wear and tear on connected machinery. This leads to fewer maintenance requirements and longer intervals between servicing, ultimately reducing downtime and operational costs.

- Versatility: These couplings are available in various sizes, materials, and configurations, making them suitable for diverse applications. Whether in a high-speed motor or a heavy-duty pump, there’s a flexible coupling designed to meet the application’s specific needs.

- Safety: Flexible couplings enhance the safety of machinery operations by absorbing shocks and dampening vibrations. They prevent sudden failures that could lead to accidents or costly damage, providing operators and maintenance teams peace of mind.

- Ease of Installation: They are relatively easy to install and align, even in applications where perfect alignment is difficult to achieve. This simplifies the setup process and reduces the time required to bring machinery online.

Contact us today to learn more about our comprehensive range of flexible couplings. Alternatively, please browse the website.